skewers

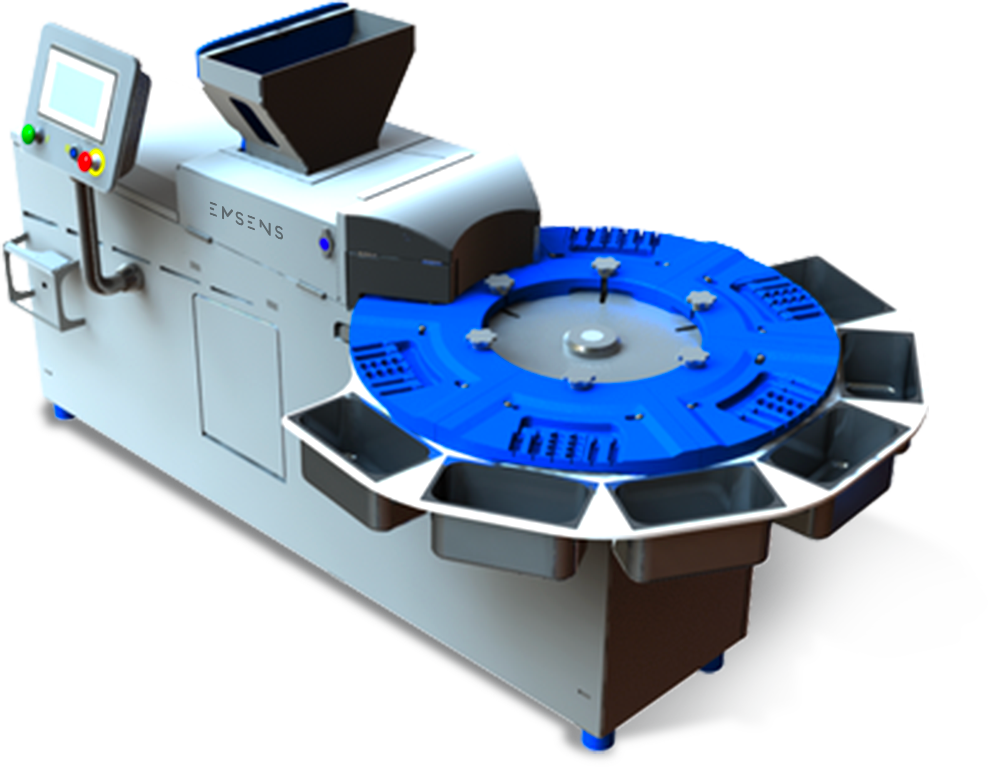

TPC02

Like the TPC01, the interchangeability of the trays allows an instant and fast change of production without cleaning the machine. The TPC02 has an automatic dispenser for cylindrical wooden skewers.

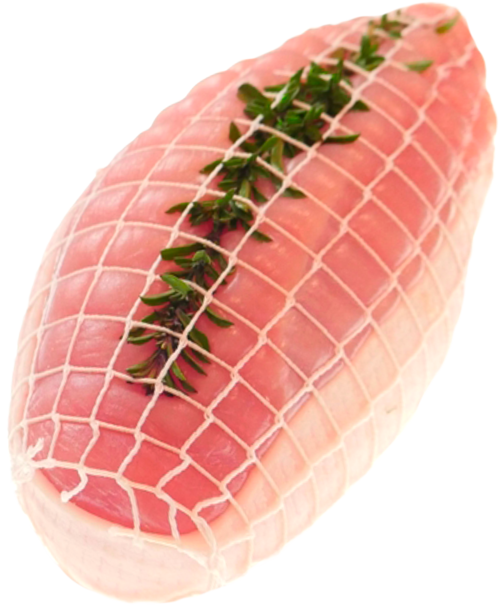

Many ingredients can be used such as meat, fish, vegetables, fruits and other processed products. The ingredients are prepared, potentially cut and then manually positioned in a tailored shape.

With each rotation of 60 ° of the tray, the machine engages the skewers of a mould, while the operators fill the others.

The shape study is personalized: it is specific to your product / machine.

Ergonomics working station to optimize the movements and moving of the operators

A touch screen makes the communication easier between the operator and the machine. The touch screen display includes a self-diagnostic system.

One cycle corresponds to the passage of one mold in front of the skewering unit that allows simultaneously the production of 4 to 6 skewers.

Maximum production rate of the machine: 800 cycles/hour.

The quantity of shapes / mold depends on the size and complexity of the skewer to produce.

Power: electrical control and pneumatic power

Materials: stainless steel and polymers

The rules dictated by EHEDG for the manufacture of machines dedicated to the food industry allow us an optimum design in order to meet your sanitary requirements.

This material is in conformity with the following directives and bills:

Food contact: EC1935/2004

Good manufacturing practice: EC2023/2006

Machines: EC2006/42

CEM: EC 2004/108

TPC02

advantages

1.

The skewers made are identical to the handmade kebabs.

2.

The skewer’s handle is not stained by marinades, thanks to an automatic horizontal skewering.

3.

Easy disassembly and cleaning.

4.

Large configuration diversity: round skewers Ø3 to Ø5mm, length from 100 to 220mm, automatic selection.

5.

Adjustable speed.