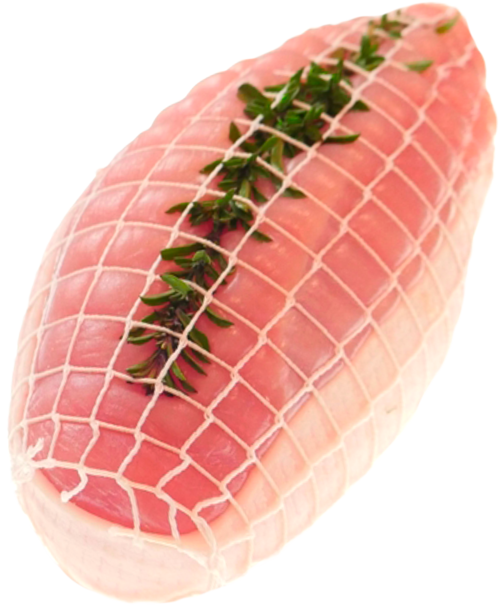

Equipped with a three-dimensional cutting system, the MDC02 makes it possible to cut cubes from raw products (pork belly) or reconstituted (in a cylinder) at a temperature of -12 ° C (± 5 ° C depending on the concentration in salt).

The loading capacity of the machine is 700 x 300 x 120 mm, the machine accepts out of shape bacon pieces.

The bacon piece is pressed to get a 210 mm wide block, it is then pushed through a bi-dimensional cutting disk to produce bacon stripes from 4 mm to 11 mm of section according to the tools used.

In the case of the use of reconstituted products up to Ø120mm, the maximum length of these cylinders is 700mm.

The cylinder is held in the cutting chamber and is then pushed through three-dimensional cutting tools making cubes with a cross section of 4 to 11 mm depending on the tool chosen.

This machine also allows the production of stamps (20 mm x 2 mm for example).

Productivity: 2 500 kg / h for reconstituted cylinders of 7.50 kg

1200 kg / h for 3.5 kg pork belly

(Cycle time of about 10.4 seconds for making 10x10x10 cubes)

Loading capacity: Up to Ø120mm (for reconstituted products)

700 x 300 x 120 (for pork belly),

Power: electrical control, hydraulic, pneumatic and electrical power.

Materials: stainless steel and polymers

The rules dictated by EHEDG for the manufacture of machines dedicated to the food industry allow us an optimum design in order to meet your sanitary requirements.

This material is in conformity with the following directives and bills:

Food contact: EC1935/2004

Good manufacturing practice: EC2023/2006

Machines: EC2006/42

CEM: EC 2004/108

MDC02

advantages

1.

This machine offers a top quality cutting. It includes a hydraulic press which allows to dice bacon pieces with a maximum bending of 120 mm.

2.

In the case of the use of cylindrical reconstituted products (up to Ø120mm), the press guides without forcing the product to the cutting device.

3.

The machine uses the EMSENS patented cutting device.

4.

The MDC02 is a machine designed to dice 2 500 kg/hour of cubes 10x10x10/ hour (with reconstituted cylinders Ø120×700 or approximately 7.5 kg).

5.

The use of pork belly (about 3.5kg) gives a productivity in 10x10x10 cubes of 1 200 kg / h.

6.

The exit of the products is done thanks to a vibrating belt.

7.

The distinction between non compliant and good products is done automatically thanks to a specific belt.

8.

Working station to optimize the movements and moving of the operators.

9.

The machine is easy to clean and takes into account the constraints of the food industry. A touch screen makes the communication easier between the operator and the machine. The screen includes a self-diagnostic system displaying a picture of the faulty component for example.